Last Updated on January 24, 2024

Stainless steel, known for its resilience and glossy appearance, is a popular choice in various industries, including cookware, automotive, and architecture. However, despite its robustness, it is not entirely immune to damage. One such issue is pitting, a form of corrosion that can compromise both the aesthetic and structural integrity of stainless steel items. Understanding the causes, prevention, and repair methods for pitting in stainless steel is crucial for maintaining its longevity and functionality. This article delves into the root causes of pitting, its susceptibility to stainless steel, and effective repair strategies.

As a result, what is the root cause of pitting in stainless steel cookware?

Pitting in stainless steel cookware primarily results from exposure to chlorides present in everyday substances like salt, cleaning agents, and coastal environments. When stainless steel is exposed to these chlorides, especially at high temperatures, it can disrupt the protective chromium oxide layer. This disruption leads to localized attacks in the form of small, yet deep, pits. The severity of pitting is influenced by factors like the steel’s composition, environmental conditions, and maintenance practices. Regular and proper cleaning, along with avoiding prolonged exposure to harsh chemicals, can significantly mitigate the risk of pitting.

One can also wonder whether stainless steel is susceptible to pitting.

Despite its durability, stainless steel is susceptible to pitting corrosion, particularly in environments with high chloride content or corrosive substances. The susceptibility varies based on the grade of stainless steel. Austenitic stainless steels, like the 304 and 316 grades, are more resistant to pitting due to their high chromium and nickel content. However, under certain conditions, even these grades can suffer from pitting. The key to reducing susceptibility lies in choosing the correct grade for the specific environment and ensuring proper maintenance and handling.

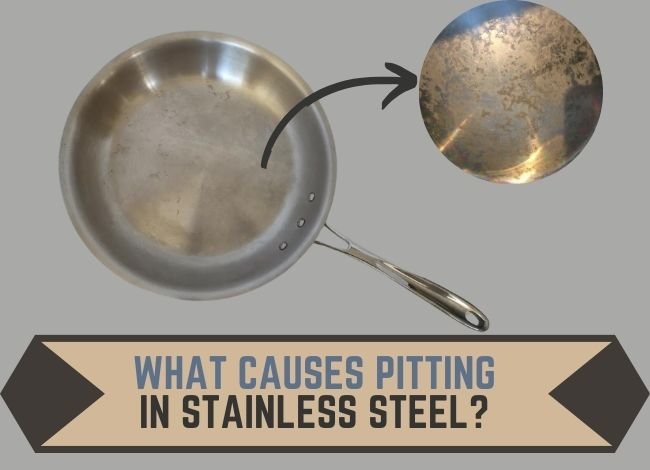

Furthermore, what exactly is pitting on stainless steel?

Pitting on stainless steel is a localized form of corrosion that results in small, yet deep, cavities or ‘pits’ on the surface. This type of corrosion is particularly insidious as it can cause significant internal damage while appearing minimal on the surface. Pitting initiates at points where the protective chromium oxide layer on stainless steel is breached, usually due to chemical exposure or mechanical damage. Once initiated, it can rapidly penetrate the metal, leading to structural weakness and potential failure of the component.

Pitting is a form of corrosion that occurs on metal.

Pitting corrosion is a specific and highly localized type of corrosion that attacks points of weakness in metals, especially those with passive protective layers like stainless steel. It’s characterized by small, pinhole-like cavities penetrating the metal. Pitting occurs when the metal’s protective layer is compromised, allowing corrosive agents to attack the metal. Factors such as the presence of chlorides, pH levels, temperature, and the metal’s composition play a critical role in the development of pitting corrosion. This type of corrosion is particularly dangerous because it’s hard to detect in its early stages and can lead to catastrophic failures.

What is the best way to repair pitting corrosion?

Repairing pitting corrosion in stainless steel involves several steps. Initially, it’s crucial to thoroughly clean the affected area to remove any corrosion products and contaminants. This is often followed by mechanical methods like grinding or sanding to remove the pits and restore the surface. In cases where pitting has not penetrated deeply, polishing may suffice. For deeper pits, welding or filling with a suitable material may be necessary, followed by grinding and polishing. Post-repair, applying a protective coating can help prevent recurrence. However, it’s important to address the root cause of the pitting to ensure long-term solutions.

What is the best way to repair stainless steel?

Repairing stainless steel effectively depends on the extent and type of damage. Mechanical polishing can be effective for minor surface issues like scratches or small pits. More intensive methods are required in cases of deeper pitting or structural damage. Welding, followed by grinding and polishing, can restore the integrity of the metal. It’s crucial to use compatible materials for welding to maintain the corrosion resistance of the stainless steel. Post-repair treatments, such as passivation, can help reestablish the protective oxide layer on the steel’s surface. Regular maintenance and protective measures are key to preventing future damage.

What foods are you unable to prepare with stainless steel?

Stainless steel is renowned for its durability and non-reactive nature, making it ideal for most cooking tasks. However, it’s not perfect for everything. Foods high in acidity or salt content, like tomato sauce or pickled foods, can cause corrosion or pitting over time. Similarly, leaving salty or acidic foods in stainless steel containers for extended periods can damage the surface. To preserve your cookware, use non-reactive materials like glass or ceramic for these foods. Remember, stainless steel is versatile but respecting its limitations will extend its life.

What is the best way to remove heat marks from stainless steel?

Heat marks on stainless steel, often appearing as rainbow-like discolorations, can be unsightly but are removable. Start by washing the surface with warm water and mild detergent. If this doesn’t work, use a mixture of vinegar and water or a non-abrasive cleaner like baking soda paste. Apply the mixture, let it sit for a moment, then gently rub in the direction of the steel’s grain. Rinse thoroughly and dry. Specialized stainless steel cleaners are available for persistent marks. Remember, abrasive materials like steel wool can scratch the surface, so use soft cloths or sponges.

What is the best way to maintain stainless steel pots from pitting?

Pitting, a form of localized corrosion, is preventable with proper care. Avoid using harsh chemicals and chlorine-based cleaners on your stainless steel pots. Instead, clean them regularly with warm water and mild detergent. Dry them immediately to prevent water spots, which can contain minerals leading to pitting. When cooking, avoid prolonged exposure to high salt concentrations; add salt to water only after it boils. Lastly, store them in a dry place to avoid moisture accumulation, which can also lead to pitting.

What causes pitting to occur?

Pitting in stainless steel is primarily caused by exposure to aggressive chemicals, particularly chlorides found in table salt, certain cleaners, and even tap water. These chlorides can penetrate the protective chromium oxide layer of stainless steel, leading to localized areas of corrosion. Factors like the steel’s grade, exposure duration, and the presence of other corrosive elements can exacerbate the issue. Understanding and minimizing exposure to these elements is key to preventing pitting.

What is the cause of the black residue on stainless steel surfaces?

The black residue on stainless steel is often a result of burnt food particles or the polymerization of oils used in cooking. This residue can be stubborn, but it’s not permanent. To remove it, soak the area in warm, soapy water, then use a non-abrasive sponge or cloth to scrub it off gently. A paste of baking soda and water, applied with a soft brush, can be effective for tougher residues. Rinse thoroughly and dry to prevent water spots. Regular cleaning after use is the best prevention method for this residue.

What is the best way to repair rusted stainless steel?

Rust on stainless steel can be alarming, but it’s often just surface-level and treatable. To remove rust, create a paste of baking soda and water. Apply it to the rusted area and gently scrub along the steel grain with a soft brush or cloth. For deeper rust, vinegar, a natural acid, can be applied before the baking soda treatment. After scrubbing, rinse thoroughly and dry. To prevent future rust, avoid prolonged exposure to moisture and corrosive materials, and consider using a stainless steel cleaner that contains protective ingredients.

What is the Source of Corrosion in Stainless Steel?

Corrosion in stainless steel, a material renowned for its rust resistance, occurs due to various factors. Primarily, stainless steel corrodes when its protective chromium oxide layer is damaged or compromised. This layer forms naturally, protecting the steel underneath from oxidation and corrosion. Factors like exposure to harsh chemicals, chlorine, and saline environments can break down this layer. Even in environments with low oxygen levels, where this protective layer cannot regenerate effectively, corrosion can initiate. Furthermore, stainless steel can corrode when exposed to high temperatures for prolonged periods, leading to scaling and reduced corrosion resistance. Understanding these factors is crucial in preventing corrosion and maintaining the longevity of stainless steel products.

What is the Difference Between Pitting and Crevice Corrosion when it comes to Corrosion?

Pitting and crevice corrosion are two common types of corrosion affecting stainless steel, each with distinct characteristics. Pitting corrosion is characterized by small, localized holes or pits on the metal’s surface. This usually occurs when chloride ions penetrate the protective chromium oxide layer, leading to aggressive corrosion in specific spots. In contrast, crevice corrosion happens in confined spaces with limited oxygen, like under gaskets, washers, or bolt heads. This type of corrosion often starts when these areas are deprived of oxygen, leading to a breakdown of the protective layer and subsequent corrosion. Both pitting and crevice corrosion can significantly compromise the structural integrity of stainless steel, making their early detection and prevention vital.

What Might Cause Stainless Steel to Corrode?

Stainless steel corrosion can be attributed to several factors. Chemical exposure is a primary cause, especially to chlorides found in industrial solvents and seawater. Physical damage to the surface can also lead to corrosion by disrupting the protective oxide layer. Environmental factors such as high humidity, salt-laden atmospheres, and pollution can accelerate corrosion. Inadequate cleaning and maintenance, leading to the accumulation of contaminants, can also cause corrosion. Additionally, factors such as contact with non-stainless metals can lead to galvanic corrosion, which occurs when two different metals are in electrical contact in a corrosive environment. Awareness of these causes is crucial for taking preventive measures against corrosion in stainless steel.

Is it possible for Stainless Steel to Rust?

While stainless steel is highly resistant to rust, it is not completely impervious. Rusting in stainless steel occurs when the chromium oxide layer on the surface is damaged or worn away. This can happen due to physical abrasion, chemical damage, or prolonged exposure to harsh environments. Once the protective layer is compromised, iron in the steel can oxidize, leading to rust. However, the extent and speed of rusting in stainless steel are much slower compared to regular steel, thanks to its chromium content. Proper maintenance, including regular cleaning and avoiding harsh chemicals, can significantly reduce the likelihood of rusting in stainless steel.

What Does Pitting Seem to Be Like?

Pitting in stainless steel appears as small, localized, and often round holes or cavities on the metal’s surface. These pits can vary in size but are typically quite small, sometimes only visible under magnification. The appearance of pitting is a clear indicator of localized corrosion, often caused by chloride exposure. Pitting is more than a surface issue; it can penetrate deep into the metal, compromising its structural integrity. The visual identification of pitting is crucial for early intervention and prevention of further damage.

What are the Different Kinds of Corrosion?

Corrosion in metals, including stainless steel, can manifest in various forms. Besides pitting and crevice corrosion, other types include uniform corrosion, which evenly affects large areas of the metal surface, and galvanic corrosion, occurring when two different metals are electrically connected in a corrosive environment. Intergranular corrosion happens along the grain boundaries of the metal, often due to improper heat treatment. Stress corrosion cracking is another form, where cracks propagate in a corrosive environment under tensile stress. Understanding these different types of corrosion is essential for diagnosing problems in metal structures and implementing appropriate protective measures.

Conclusion

Understanding the causes and types of corrosion in stainless steel is vital for its maintenance and longevity. While stainless steel is known for its corrosion resistance, factors like chemical exposure, environmental conditions, and physical damage can lead to various forms of corrosion, including pitting and crevice corrosion. Regular maintenance, proper cleaning, and awareness of the environment in which stainless steel is used can significantly reduce the risk of corrosion. By recognizing early signs of corrosion and taking preventive measures, the integrity and functionality of stainless steel can be preserved for extended periods.