Last Updated on December 4, 2023

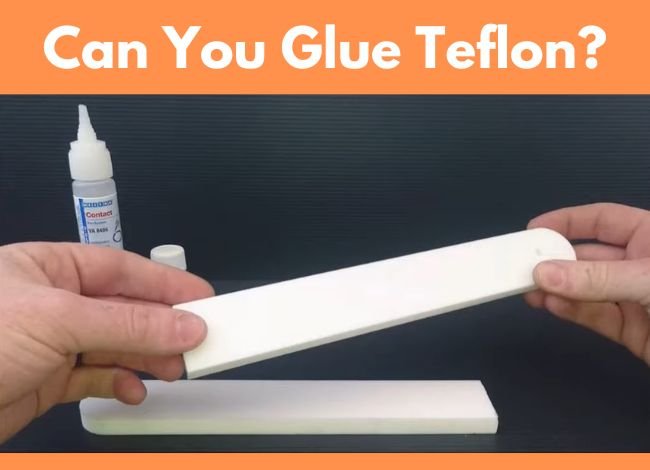

Teflon, also known by its chemical name polytetrafluoroethylene (PTFE), is a synthetic polymer renowned for its non-stick properties. This is the reason it’s frequently used in cookware, pipes, and various industrial applications. But what about when we want to join Teflon to itself or other materials? Can Teflon be glued? This article delves into this question, the challenges surrounding it, and potential solutions.

The Nature of Teflon

Teflon is unique because of the chemical makeup of its surface. It has one of the lowest coefficients of friction against any solid, which means things don’t easily stick to it. This is beneficial for cookware, where we want our scrambled eggs to slide right off the pan, but not necessarily when we want to glue two pieces together.

The molecules on the surface of Teflon are tightly packed and are hydrophobic, meaning they repel water and, by extension, many other substances. This trait makes Teflon an excellent choice for sealing and gaskets because it doesn’t react with or adhere to most substances, including many adhesives.

Challenges with Gluing Teflon

- Low Surface Energy: Teflon has a very low surface energy. For a material to be glued effectively, the adhesive must “wet out” the surface. This means that the adhesive needs to spread out evenly to form a bond. Due to its low surface energy, most adhesives will bead up or not stick at all to Teflon.

- Chemical Resistance: Teflon is known for its chemical resistance. This is fantastic for many applications but poses a challenge for adhesives that rely on chemical bonding. The non-reactive nature of Teflon means that chemical-based adhesives have a tough time securing a grip.

- Temperature Resistance: Teflon can handle a wide temperature range without degrading. While this is an advantage for its intended uses, it can be a challenge for adhesives that might degrade or lose their bonding capabilities at these temperatures.

Potential Solutions

While gluing Teflon is challenging, it’s not entirely impossible. There are methods and specific products developed with the intention of adhering to difficult-to-bond surfaces like Teflon:

- Surface Treatment: Before using any adhesive, treating the surface of Teflon can enhance its bondability. One popular method is called “etching.” A sodium-naphthalene solution can be used to etch the Teflon surface, making it more amenable to bonding. This etching process creates microscopic grooves and changes in the surface chemistry to make it more adhesive-friendly.

- Specialized Adhesives: While standard adhesives may not work, there are specialized adhesives, often epoxy-based, that have been formulated to bond with Teflon. These adhesives usually come with specific instructions and may require the previously mentioned surface treatments.

- Mechanical Bonding: Instead of trying to glue Teflon directly, some applications might benefit from mechanical means of attachment, like screws, clips, or other fasteners. If the design permits, combining a mechanical bond with an adhesive can create a more secure attachment.

- Heat Welding: For bonding Teflon to Teflon, heat welding is a possible solution. The two pieces are melted together at the seams, creating a bond once they cool and solidify. This requires special equipment and expertise but can be a reliable way to join Teflon materials.

Alternatives to Teflon

If adhering Teflon becomes too much of a challenge for a particular application, it might be worthwhile to consider alternative materials. There are other fluoropolymers and plastics that, while not having the exact properties of Teflon, might be easier to bond while providing similar functional benefits.

Related Articles:

- Hard Anodized vs Ceramic Cookware: Complete Guide

- Granite Cookware vs Ceramic Cookware (What You Should Know)

- In-Depth Product Review: Williams-Sonoma vs. All-Clad Cookware

- Cuisinart vs. Rachael Ray Cookware: A Comprehensive Review and Comparison

Conclusion

Teflon’s unique properties, while making it an invaluable material in various industries, also present challenges when it comes to gluing or bonding. Traditional adhesives are typically ineffective on Teflon due to their low surface energy, chemical resistance, and temperature resilience. However, with the right techniques, such as surface treatment or specialized adhesives, and sometimes a mix of mechanical and adhesive bonding, it is possible to adhere Teflon to itself or other materials.

It’s crucial to understand any project’s specific requirements and test any bonding method or adhesive on Teflon before large-scale application. When in doubt, consulting with material scientists or adhesive specialists can provide insight into the best strategies for your specific Teflon-bonding needs.